In the last year of mechanical engineering at the University of Alberta each student takes part in a year long project in groups of 3-4. I teamed up with fellow classmates to work on our U of A FSAE car. We choose to work on a new clutch and shifter design that would allow for the drive to shift without removing their hands from the steering wheel, and eliminate the need to let off the throttle during upshifts. The system was to cost less than $1500, weigh under 15lbs, and be able to upshift in under 0.5s. We designed a pneumatic system to achieve these goals. I was in charge of determining the appropriate pneumatic system, and do so by creating an extensive excel spreadsheet with an iterative solver, to estimate the performance of our pneumatic shifting system. This spreadsheet was used to determine the size and pressure needed in our compressed air storage tank, as well as specify the appropriate size actuating cylinders. I also used it to predict the actuation time of our system. I predicted an actuation time of 0.25s, with a total of 1800 shifts per charged air tank. Our system design came in at a predicted weight of 14lbs, but above budget at $2235 (the pneumatics being the largest cost items).

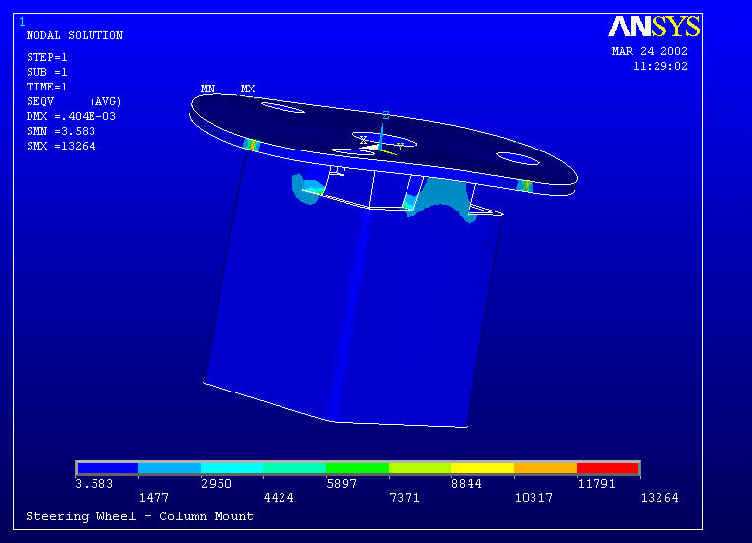

We also designed a steering wheel that could be easily removed and attached the drive shaft, while making reliable electrical connections. I was charged with performing some FEA on our steering wheel mount to ensure it’s safety.

Our team received the highest mark possible in this class (7/7).

Tools used:

- Pro/Engineer 19

- Excel

- ANSYS 5.7